EXPERTLY

DESIGNED

FOR YOU

Every product we design aims to make your life easier

A brand new project, a new component or simply a restoration?

More than just a Design Service.

We are your trusted partner for reliable designs, expert support and machining capabilities.

We will provide you with a friendly, one to one consultation and offer helpful advice from concept to manufacture.

How it works

1. Send us a Request - whatever the size of your project

Big or small, contact us to see if, with our specialist knowledge, we can help.

You can trust us to be professional and confidential throughout.

2. Discuss details on a one to one basis

We will need to take details and measurements from you.

Describe the item or project to us and with this information and understanding we can then work out how to proceed.

3. Decide on a way forward together

Decide on a way forward together and agree lead times, costs and any other details.

4. Start project

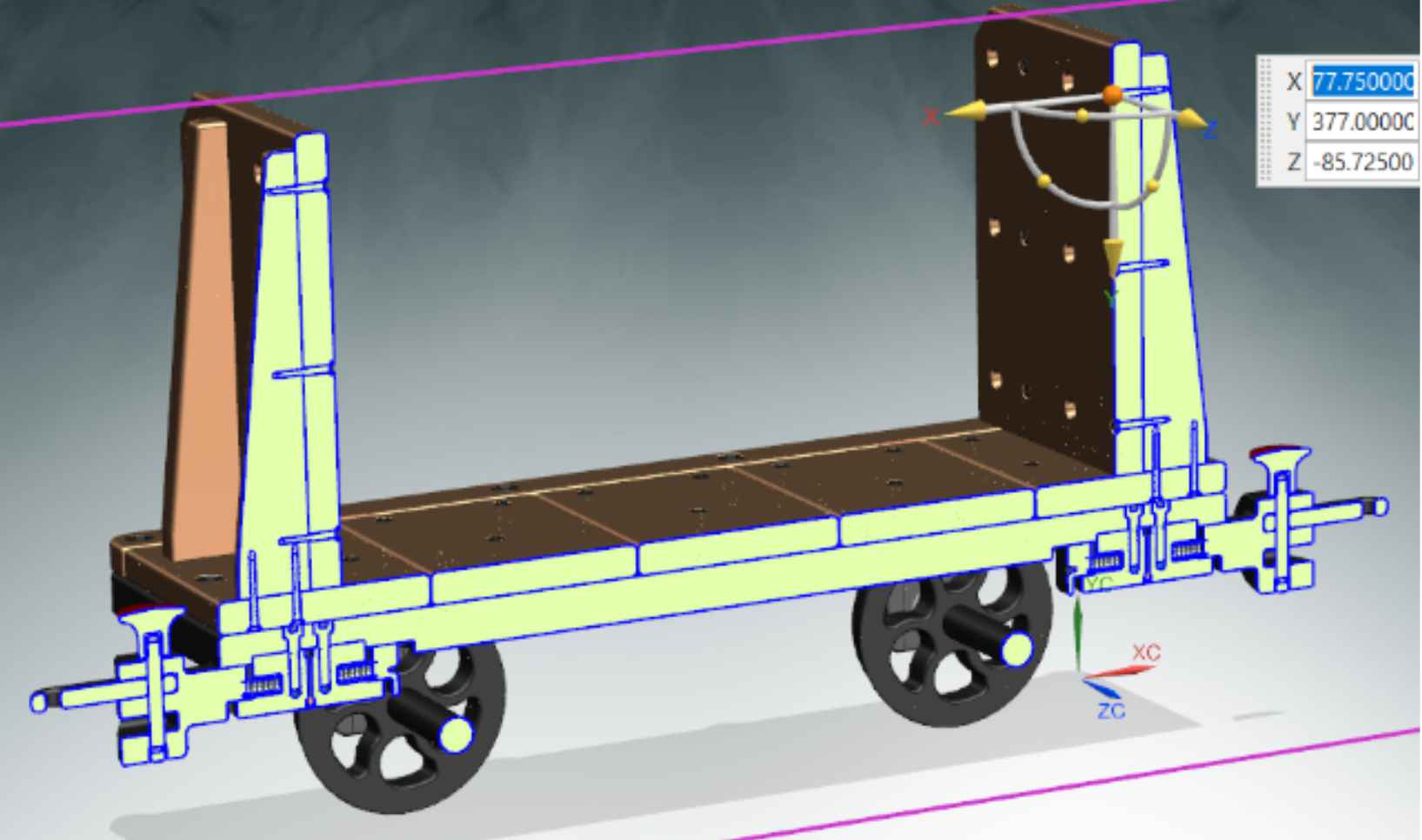

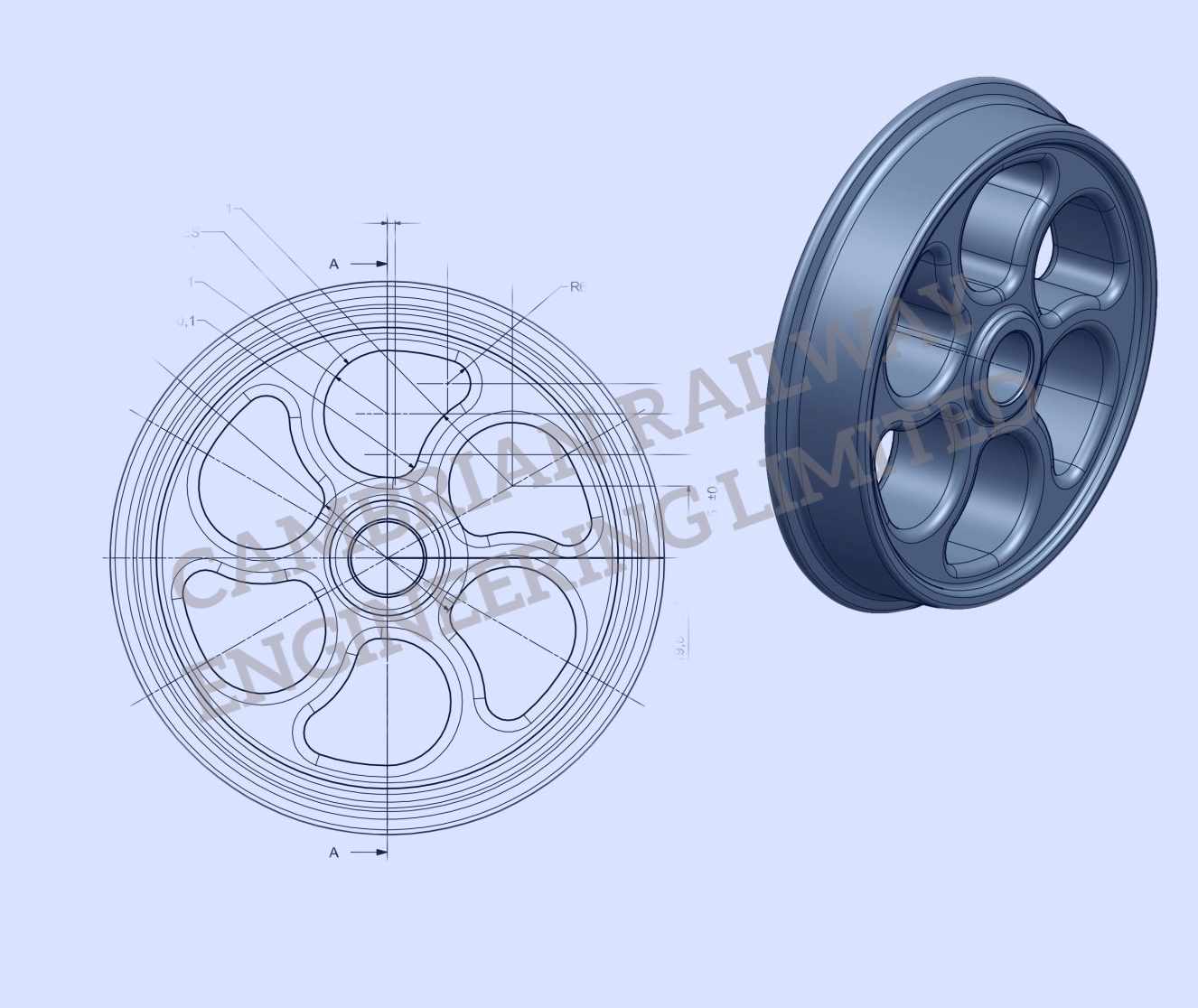

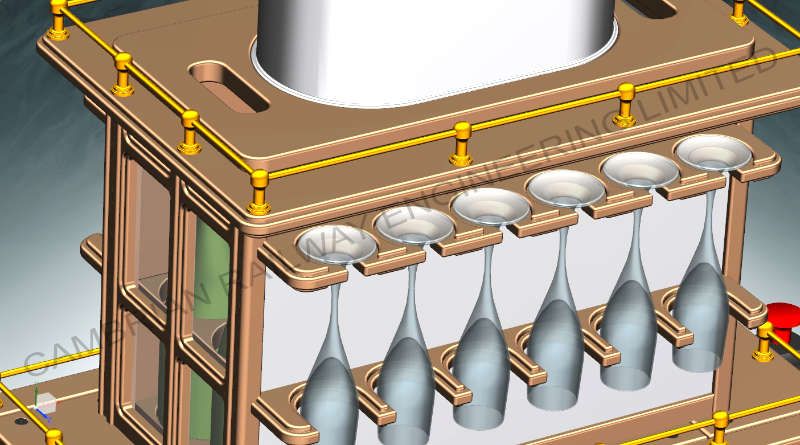

Starting with initial sketches, we will produce CAD models followed by detailed CAD drawings of your design for your approval.

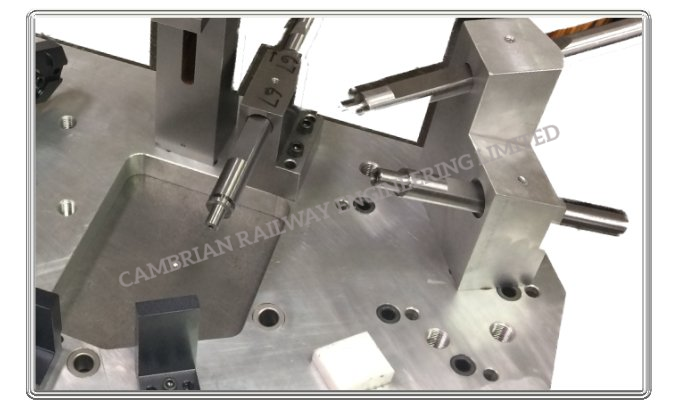

During the manufacturing stage, you are welcome to visit us and see your components being manufactured.

5. Finish on schedule with after market support

We will make every effort to complete your project within the agreed timescales. Delivery of components will be to your specified requirements.

We always like to provide after market support at the point of need so don't hesitate to get back in touch with us.

From concept to completed manufacture

We offer our personal one to one,

specialist design services to you.

A perfect collaboration for -

Engineering enthusiasts

Prototype projects

For one off's and low volume production

OUR TECHNICAL DESIGNS...

...BECOME YOUR REALITY

Testimonials

Excellent quality. Superb items. Excellent people to deal with.

Hoping to be back in touch.

Mark, Milton Keynes

Just a quick message to thank you and your wife for delivering my chassis, I would just like to congratulate both of you for producing such a high end product, I had a good look around it on Sunday and I'm really impressed with it and making it into a tender for my loco will be an easy process saving me a massive amount of valuable time. Thanks again

Regards K

K, Lincolnshire

Hi, just wanted to say thanks, wheels arrived safe and sound and well with me, lovely wheels, just wondering if you have more in stock? I have a further project in mind. Thanks.